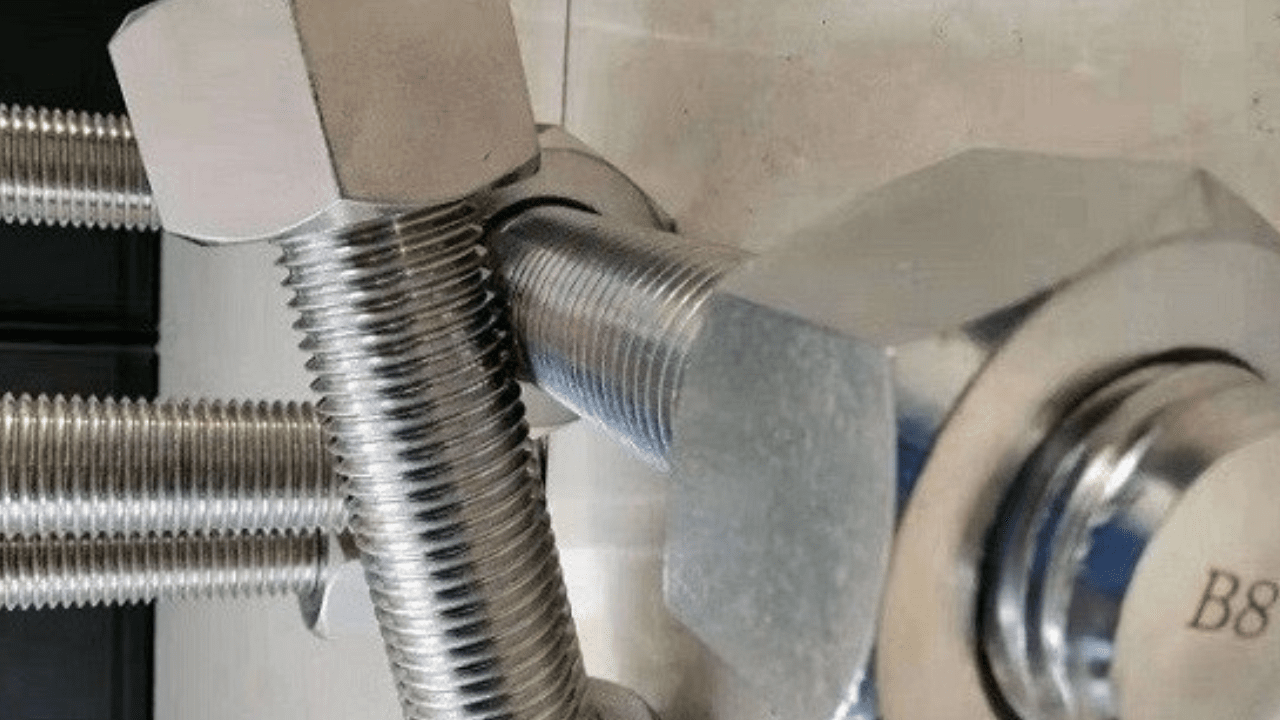

How 304 is Different from 316 Stainless Steel Screws?

Their erosion opposition is central, making them ideal for outside applications, marine conditions, and areas presented with cruel synthetic compounds. Also, stainless steel screws gloat extreme Adaptable energy and durability, guaranteeing life span and dependability in distressing circumstances.

Their non-attractive homes lead them to be important in delicate electronic and logical gear wherein attractive impedance should be deflected. To find out more specific information on the stainless steel screws, click the link https://www.a2fasteners.com/stainless-steel-screws/. Their flexibility, combined with protection from rust and checking, highlights their significance in creation, vehicle, aviation, and endless different fields, where best and execution are non-debatable.

304 and 316 Stainless Steel Screw Differences

304 and 316 stainless steel are each popular picks for screws and other fasteners, but they have got different compositions and residences that cause them to be appropriate for distinctive tasks.

Composition and Properties

304 stainless steel, furthermore known as A2 hardened steel under the ISO 3506, is an austenitic tempered steel with an organization of 18% chromium and 8% nickel. This piece presents exceptional erosion obstruction in different conditions, which incorporates freshwater, moderate acids, and air circumstances. Additionally, it offers true weldability and formability, making it appropriate for a wide variety of packages, from family appliances to architectural systems.

Then again, 316 stainless steel, or A4 stainless steel in ISO 3506, consists of a better chromium content material of 16-18% and provides 2-3% molybdenum to its composition. This molybdenum addition complements its corrosion resistance, mainly in chloride-wealthy environments such as marine settings and business packages wherein exposure to corrosive chemical substances is well-known. Therefore, 316 stainless steel is famous for superior resistance to pitting and crevice corrosion, making it the favored preference for marine hardware, chemical processing equipment, and medical gadgets.

Corrosion Resistance

Consumption Obstruction Quite possibly the most incredibly enormous qualification somewhere in the range of 304 and 316 stainless steel screws lies in their erosion obstruction homes. Simultaneously as each amalgams give magnificent consumption opposition, 316 stainless steel beats 304 in more extreme conditions, primarily those containing chlorides like seawater or de-icing salts.

The molybdenum in 316 stainless steel offers assurance resistance to chloride-prompted consumption, making it the ideal longing for seaside and marine projects in which erosion obstruction is vital. In evaluation, 304 stainless steel could likewise encounter limited consumption, which incorporates pitting erosion, in chloride-rich conditions. In any case, it remains a top-notch craving for indoor and outside programs in which openness to destructive specialists is the least. The right support and occasional cleaning can enhance the supplier’s ways of life of 304 stainless steel screws in somewhat destructive conditions.

Power and Strength

In expressions of mechanical houses, each 304 and 316 stainless steel screws give top-notch strength, flexibility, and life span. Notwithstanding, the expansion of molybdenum in 316 stainless steel supplements its standard strength and toughness, especially at sped-up temperatures. This makes 316 stainless steel screws more prominent and appropriate for over-the-top temperature bundles where mechanical pressure and consumption are goliath concerns.

Besides, 316 stainless steel notably shows progressed protection from strain consumption breaking (SCC) when contrasted with 304 stainless steel, particularly in chloride-rich conditions. This trademark is fundamental in businesses that incorporate petrochemical, drug, and food handling, wherein the trustworthiness of latches is urgent for security and unwavering quality.

Application

304 stainless steel screws are normally used in household home equipment, architectural furniture, automobile components, and preferred-motive fasteners. Their corrosion resistance and affordability lead them to be suitable for diverse indoor and outdoor applications. Then again, 316 stainless-steel screws are preferred in marine hardware, chemical processing equipment, pharmaceutical gadgets, and aerospace additives because of their splendid corrosion resistance, specifically in chloride-wealthy environments. Regardless of their better price, the advanced sturdiness and reliability of 316 stainless steel cause them to be critical in industries in which corrosion resistance is essential for protection and performance.

Cost

Even though 316 stainless steel gives more suitable corrosion resistance and sturdiness, it normally comes at a better cost than 304 stainless steel. The expanded molybdenum content and other alloying elements make contributions to the better price of 316 stainless steel screws. Therefore, when deciding between the 2 grades, it’s important to remember the unique utility requirements, financial constraints, and long-term protection expenses.

Final Thought

Simultaneously as each 304 and 316 tempered steel screws offer consumption obstruction and strength, their varying pieces make each fitting for extraordinary applications. 304 stainless steel is flexible and financially savvy, ideal for stylish use, while 316 stainless steel succeeds in destructive conditions like marine and synthetic settings. Mastery of these differentiations licenses proficient decision-making for best quality level execution and durability in different ventures.